I had been selling these, but have ceased production as it wasn't economic. Things may change one day as I am negotiating with a major outdoors gear vendor for production.

For winter use the tent design has to be a tunnel with a double skin. A tunnel rather than a dome because the tunnel is more stable (unless you get into quite heavy geodesic designs); a double skin is needed to keep the snow out. Yes, this means that 'winter' really does put the focus on snow use. For ordinary bushwalking in winter at moderate altitudes the summer tent would be fine. If you are intending to be above the tree line a lot, then it's a toss-up. I use my summer tent in the Australian Alps above the tree line, but I select my sites with some thought to wind.

Incidentally, you may find that in America they sell what they call 'double skin 4-season' tents where the inner tent is just netting. Well, the netting inner does keep the bugs out of course. But do not ever think that these are genuine 4-season tents, because they are not. They are single-skin tents with bug netting, and usually they are for mild weather only.

The first version I made used three hoop poles and is called the 'orange' tent. It can also be seen on the Ultra-lightweight page and the Stove page. The orange one in the pictures uses the NASA balloon fabric, but the design works just as well with the silnylon fabrics. It had to use pre-bent aluminium poles as the radius of curvature needed is way beyond what can be safely done with straight aluminium or carbon fibre poles. You can use straight aluminium poles, for a while, but this takes the poles a factor of about three beyond their elastic limit and eventually results in a fracture - trust me, I know! (It happened twice in one long trip.)

If you want to use carbon fibre poles, as I do in all my tents these daya, you must use bends. You simply cannot put this much bend into carbon fibre tubing without a failure (but the forces would be quite high!). I have therefore upgraded this winter design to take carbon fibre poles. I use three bends per pole, as for the summer tents, and I have increased the number of poles to four. The reduced fabric span and the extra pole for strength gives enormous stability in bad weather. On the (somewhat epic) trip on which this photo was taken the tent took winds well over 100 kph when rather unwisely I camped almost on top of Mt Anton on the Main Range in KNP, the night after this morning. That was right in the path of the storm. What made it worse was the fact that most of the Spectra guy ropes frayed away during the night - and yet the tent survived, and so did we. You can read the full story in When Things Go Wrong at Backpacking Light. There is a moral here about retreating when things go seriously pear-shaped.

The tent shown in the first picture was the 'orange' prototype. It is almost symmetrical - the doors themselves were slightly different but this is not visible here. We found in practice that it was very easy to always use the end with the better door design as the main entrance and the other end as the pack store. But in a bad storm you never want to open the windward door - if you want the tent to stay on the ground. So we had to pass the packs through the tent to the lee end in bad weather, which was a bit of a pain.

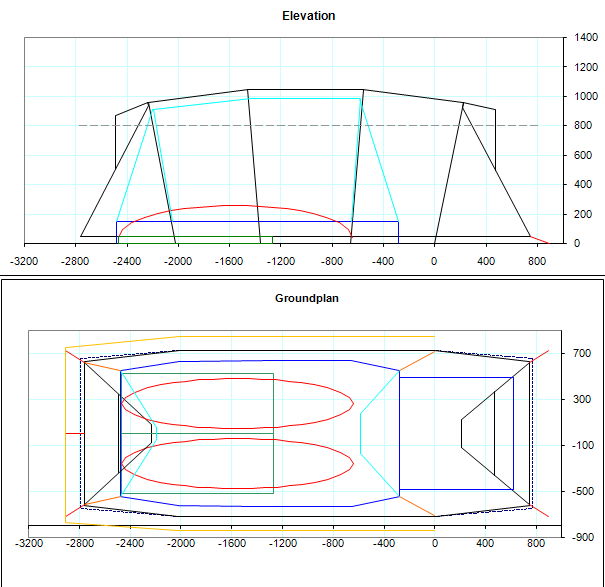

Eventually I decided to go asymmetrical, with a large vestibule at the lee end for packs and cooking, and very little space at the windward end. I then reinforced the windward end with a bit more in the way of guys and anchors. As you can see from the line drawings below, the tent uses four poles or hoops to get its characteristic shape. It has an asymmetric inner tent of similar shape to stop the wind and the snow. For this reason the two end bells themselves are slightly different as well.

Some much simplified line diagrams for the tent are thus. The green rectangles represent 3/4 length air mats, and the red ovals represent bodies in sleeping bags - bodies of about medium height. The funny corners at the top ends in the side view drawing are the storm hoods over the windows at the tops of the doors. Even with the windows open (essential to prevent condensation), heavy rain does not come in.

These drawings show the outline but not the pole shape. You can get that from the previous photo. The weight of this version using silnylon and carbon fibre is about 1650 grams (tent plus poles), which is lighter than my first orange tent which came in at about 2kg. An approximate weight schedule for the materials follows shortly. It is interesting to note that the four carbon fibre poles weigh less than the three aluminium poles in the orange tent. Most of the notes for the summer tent are generally applicable here too.

This design is not frozen either. It too has been described mathematically (conic sections etc) and can be varied. However, it has been tested!

Both the silnylon (49 gsm, 60 kPa) and the orange NASA fabric (55 gsm, >100 kpa) are nice fabrics, and both are very slippery, so snow will slide off them very easily. This is better than many other tents which have a nylon fabric outer surface (with PU on the inside) to which the snow can stick. However, after several snow trips I found the orange NASA fabric had problems. The thick orange PU layer you can see in the photos gets very stiff in the cold, and the nylon fabric on the inside can absorb water and get heavier, and even freeze. I found myself folding up sheets of ice, and worrying whether the fabric could handle that. I have since switched entirely to the silnylon fabric. This does not absorb any water and has a fantastic temperature range.

The inner tent has to be spaced a little inside the fly to avoid having them stick together. This can happen under conditions of high humidity and falling temperature, which can cause some condensation on the inside of the fly. I initially tried a spacing of 50 mm, but this was too little. I found there could be contact under severe weather conditions - just when you really don't want any problems. On one or two occasions the inner tent actually stuck to the fly - by icing up. I now favour a spacing of about 70 mm. Adding 25 mm to the height of the outer tent seems a small price to pay for the improvement. Yes, I made the outer bigger rather than the inner smaller: we value our headroom and living space, and the extra weight this added was pitiful - maybe 20 g.

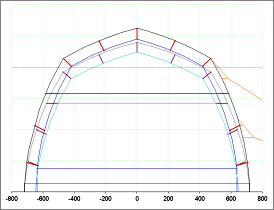

The inner tent is attached to the outer tent by hook&loop joiners at each arch. They are the short lines going from the outer fly to the inner tent. There are two profiles shown in this diagram: the bigger (darker) one is for the middle poles, while the smaller profile is for the end poles. I use a narrow hook&loop strip but quite a few joiners, and this gives me a good curve with no sags on the inner tent. These links can be adjusted to get optimal tension, and do allow you to separate the two for repairs. I do not advocate splitting the two for packing: that's a myth and a complete waste of time. Reassembling the two in a storm (joining up all those hook&loop links) is seriously bad news as well - it takes ages. Meanwhile you are getting wetter and colder.

The doors are located at the poles and go down to the groundsheet. You will notice that the poles definitely lean outwards: this means the entire door is outside the groundsheet. This is different from many dome designs which have the door over the groundsheet and the overhang ensures any drips (or heavy rain) land on the ground, not on the groundsheet. Such a design is raving idiocy! The inner tent door is made of the same fairly windproof fabric as the inner tent, and is closed with a zip to keep snow out. Just outside this inner door there is a netting door, although I am really not sure it was needed. You can have the windproof door open and the netting door shut in fine weather: standard stuff. Or you could probably omit the netting door completely, if you are confident about always being above the bug limit.

The inner tent is not arranged symmetrically, as mentioned. It has been pushed to the 'rear' of the tent, and this very deliberately allows a huge amount of vestibule space. We can put our two packs in the vestibule (one on either side) and have plenty of room for cooking in the middle. However, by arranging the inner tent to meet up with some of the poles I have managed to keep the inner tent fairly well tensioned.

| Item | Description | weight per | Weight | |

|---|---|---|---|---|

| Fly | Silnylon | 49 gm/sqm | 503 gm | |

| Inner Tent | DWR breathable nylon | 32 gm/sqm | 342gm | |

| Netting | Knitted | 19 gm/sqm | 30 gm | |

| Groundsheet | Silnylon | 49 gm/sqm | 206 gm | |

| Poles | Carbon fibre, SS bends, Al joiners | 34 gm/m | 310 gm | |

| Zips | Nylon coil #3 | 12 gm/m | 104 gm | |

| Sundries | Thread, bungee cord, Velcro, etc | 150 gm | ||

| Total | 1646 gm |

The first (NASA) orange tent shown used a white medical material (80 gsm) for the groundsheet, but this was overkill. The coating was fairly heavy (and good), but the fabric was no stronger. You do not need a high pressure rating in the snow: any water at floor level will sink into the snow. The worst case is probably when you are pitched on sheet rock without a mattress. I have quoted the silnylon weight as I have found this is quite adequate, and I use it on the summer tents as well. I assume you will take some care of your tent, but in the event of any accidents repairs are quite easy.

The original poles were a fairly lightweight Easton 0.344" poles at 34 gm/m. These had to be pre-bent, otherwise they would work harden and snap. The 7075 T9 alloy used was fairly reliable; the newer and slightly lighter ones of 7178 alloy are just a bit too brittle. The cheaper 7001 T6 alloy found on some other brand poles is weaker, and makes the poles heavier (although the new DAC Featherweight poles might be better). However, the carbon fibre tubing I am now using is very strong and far lighter - either a Victory arrow VForce 400 or an Easton Ion pole would be fine. With the silnylon fabric it is very easy to insert and withdraw the poles from the sleeves, even in the snow. I use bungee cord inside the poles to hold them together, and short lengths at the pole-ends to tension the roof over the poles - all as for the summer tent.

Other items such as zips, bungee cord, eyelets etc are as for the summer tent. There is a surprising number of little bits involved, and I found that it was really necessary to scrutinise every item to keep the weight down.

Near the end of 2012 Colin built his version of this design. Like Sven he too used a wooden frame to create the patterns, and external aluminium elbows. He stretched black plastic over the frame to make the patterns. Fabric was from Outdoors Wilderness Fabrics ('OWF') in America. The photos here are all his.

For poles he used carbon fibre kite tubing, Skyshark P300 from Goodwinds in the US. Yes, you can buy it over the web. For the straight joiners he used short bit of smaller CF tubing joiners glued inside with Araldite. For the elbows he used 10mm aluminium tube fitted over the outside. Bending the Al tubing was quite a bit easier than bending the SS tubing I used: you can buy small tubing benders from eBay which might work with tubing this small. One of them is shown here. Others (eg Sven) have also used external Al tubing for this quite successully.

There is always a problem with external elbows though: the end of the pole can get jammed inside the elbow where it starts to bend. This can damage the CF tubing. Colin solved this very neatly: he cut some ~6 mm lengths of CF tubing and forced one bit up inside the elbow from each end to the curved part of the bend. This bit of tubing did jam in place of course, but it acted as a stopper for the pole. I thought this was rather clever. He also used a zip down the middle of the netting doors rather than an overlap.

Colin wouldn't say how many hours it took him to make the tent - quite a few I gather. No matter - making gear is part of the fun. The completed tent is shown here at home. However, as soon as he finished it he took it on a '9 day hike on the South Coast track in Tassie over Christmas so it very quickly got tested out. Had a couple of nights with rain and only one small leak where I hadn't quite sealed the floor properly where I had sewn through to attach the pole eyelet tag. [A small tube of silicone sealant is your friend.] A bit of wind some nights but no howling gale.'

The photo to the left here shows the tent pitched at the Ironbounds in Tassie. The pitch is a bit slack: Colin said that this photo was taken in the morning after rain, and the nylon had gone a bit floppy. A bit more tension on the bungee cords at the ends in the evenings would fix that I think. Also, the poles in these two photos are straight, whereas they should be quite curved as shown in the second photo (red tent) on this page. We think this was due to making the corners have too much of an angle. That can be fixed very easily with a bit more aluminium tube.

Colin mentioned that the old whipper snipper cord he used at first for the edges of the verandahs was very curly, and this was a real problem for the verandahs. You can see the problem in some of the photos. He solved this by getting some new plastic whipper snipper cord which did not have as much of a set in it. You can also use something like 1 mm copper wire with the ends curled up. It gets bent when you roll the tent up, but it can be straightened in the field each time. Some commercial tents do it this way.

© Roger Caffin 6/6/2002, 20/06/2009, 27/1/2013